The variety of plasticizers in rubber: An overview

When selecting plasticizers for rubber, experts consider various criteria to ensure that the materials meet the requirements of the respective application.

Important criteria include:

- Compatibility with rubber in terms of polarity and reactivity

- Physical properties such as viscosity, density, pour point, and aniline point. The viscosity of the plasticizer influences the molecular weight and processability of the rubber compound.

- Temperature resistance

- Volatility

- Cost

- Environmental impact

- Additional requirements such as flexibility, hardness, chemical resistance, and flame retardancy

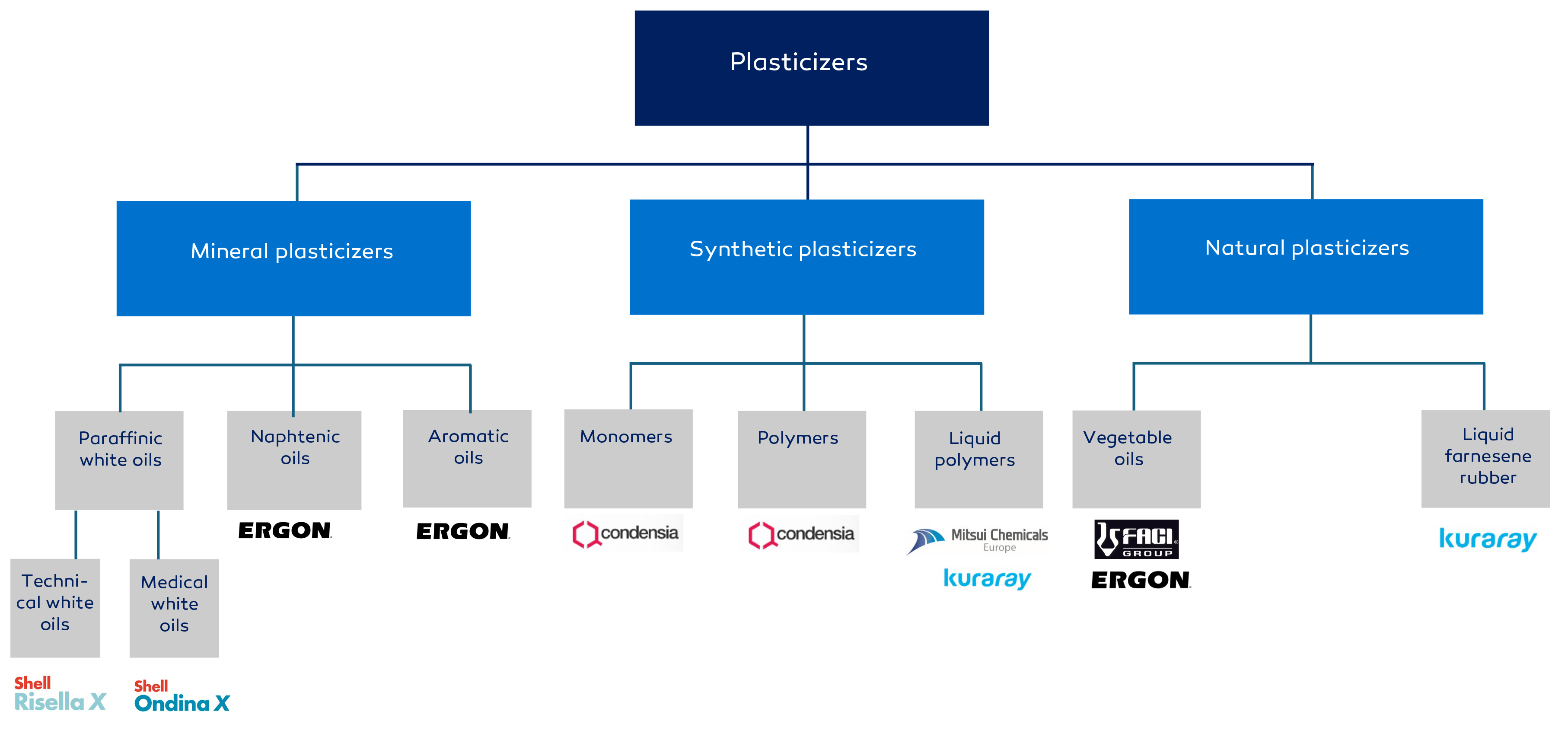

Plasticizers are often classified according to their origin into mineral oil-based, synthetic, and natural plasticizers. For special requirements, Nordmann has additional, specialized plasticizer solutions in its portfolio.

Mineral oil-based plasticizers

Mineral oil plasticizers, which are derived directly from petroleum, are mainly used to extend and reduce the cost of polymers and can be divided into paraffinic, naphthenic, and aromatic oils (depending on which component predominates).

Paraffinic mineral oils: These mineral oils are suitable for UV-resistant vulcanized products and are characterized by good solubility. Experts distinguish between white oils according to their degree of purity, classifying them as technical or medical grades. Medical white oils meet the strict requirements of international pharmacopoeias such as the European Pharmacopoeia (Ph. Eur.) and the US Pharmacopoeia (USP).

- Technical white oils: Shell Catenex T and Shell Risella X oils are highly refined process oils produced using different methods. Shell manufactures Catenex T oils using a solvent extraction process, while Shell Risella X oils are based on innovative gas-to-liquids (GTL) technology. Both oils are characterized by their virtually colorless and sulfur-free composition. This makes them ideal for use in rubber compounds. As plasticizers, they offer excellent color stability, low volatility, and low sulfur levels. Technical white oils increase the chain mobility of polymers. This improves the elasticity and durability of rubber compounds, contributes to even distribution of fillers, and reduces hardness. This results in improved flexibility and longer service life for end products. Shell Catenex T and Risella X oils are compatible with a wide range of polymers, including BR, EPDM, IIR, and NR.

- Medical white oils: Shell Ondina oils are aromatic-free, paraffinic white oils. As plasticizers in rubber compounds, they offer excellent color stability, low volatility, and low sulfur content. Shell Ondina oils are compatible with a wide range of polymers, including BR, EPDM, IIR, and NR.

Naphthenic mineral oils: Naphthenic mineral oils are another type of mineral oil plasticizer used in rubber processing and contain mainly naphthenic, i.e., cycloalkane compounds.

- Process oils: HyPrene oils from Ergon International are produced by refining crude oil. Compared to paraffinic products, they offer higher solubility and thus help improve the physical properties of elastomers. Their properties (including significantly lower pour points) also make them ideal for processing at low temperatures. HyPrene is compatible with many polymers (e.g., NR, SBR, EPDM, BR, and NBR). Nordmann partner Ergon International offers it in various viscosities.

- EcoPrene process oils from Ergon International are partially bio-based oils that have an improved environmental balance and are ISCC+ certified.

Aromatic mineral oils: Aromatic mineral oils such as TDAE, RAE, and MES are popular due to their low cost and good solubility. They improve the dispersion of carbon black and result in increased tear resistance and better tear resistance.

- Aurora Process Oils from Ergon International are a sustainable alternative to aromatic mineral oils and are 100% bio-based.

- Naphthenic mineral oils can also replace aromatic mineral oils thanks to their composition and properties. For example, Hyprene L2000 from Ergon International can replace TDAE and RAE, while Hyprene L1200 is a good substitute for MES.

Synthetic plasticizers

Synthetic plasticizers include monomeric and polymeric esters, phosphates, ethers and thioethers, phthalates, and liquid polymers.

Monomeric esters are synthetically produced by reacting carboxylic acids with alcohols. Depending on the carboxylic acid and alcohol used, these esters can be divided into adipates, sebacates, and trimellitates, among others:

- Adipic acid esters (adipates) such as Glyplast DOA and Glyplast DIDA from Condensia are frequently used to improve the low-temperature properties of elastomers. They offer a good combination of low volatility and cold behavior. In addition, they are particularly suitable as plasticizers for polymers such as ACM, AEM, CR, or NBR, making them excellent alternatives to phthalates. Glyplast 801 and Glyplast 803 are optimized adipic acid esters with service temperatures optimized compared to DOA and DIDA, covering ranges from -50 to 175-180 °C.

- Sebacic acid esters (sebacates) such as Glyplast DOS and Glyplast DIDS are mainly used to optimize cold flexibility as they have excellent low-temperature properties. They also offer excellent resistance to aging and oxidation. This extends the service life of rubber products. Sebacate plasticizers are also known for their low volatility, which results in lower emissions of volatile organic compounds (VOCs). Their high compatibility with various elastomers such as CR, CM, CSM, and NBR makes them versatile and significantly improves the mechanical properties of rubber compounds.

- Trimellitic acid esters (trimellitates) offer very low volatility and good resistance to high temperatures. They are often used as a substitute for phthalates and are highly compatible with ACM, AEM, NBR, and HNBR. Glyplast TML810 from Condensia consists of 70% sustainable raw materials and thus makes a significant contribution to sustainability. In addition, it offers higher heat resistance than Glyplast TMO (also known as TOTM). Phthalates: DINP, DOTP, DOP, DIDP, and Glyplast DTDP

- Selected phthalates are already classified as toxic to reproduction. According to the US Environmental Protection Agency, DINP and DIDP are also suspected of accumulating to high levels in organisms. Ergon International has developed an alternative for industrial applications based on sustainable raw materials: Aurora PHFree.

Polyester plasticizers are polymerized esters and can be produced as reaction products of alcohols and carboxylic acids.

- Polymerized ester plasticizers are characterized primarily by increased migration and extraction resistance. They also offer excellent compatibility with various polymers such as NBR/PVC, HNBR, and CO/ECO. The polyester plasticizers in the Glyplast 206/X NL series from Condensia cover a wide viscosity range (850–9000 cP). They have low volatility and are highly stable at high temperatures. The Glyplast 20K/X NL series of plasticizers from Condensia is characterized by increased temperature and water resistance. Glyplast 1070C, with a viscosity of 15,000 cP, is suitable for extreme migration resistance requirements.

Phosphates or phosphoric acid esters can often be used as flame-retardant plasticizers. They are only compatible with non-polar rubbers in small quantities.

Liquid polymers

- KURARAY LIQUID RUBBER comprises liquid isoprene rubber (LIR) and liquid butadiene rubber (LBR). These high-viscosity synthetic rubbers are based on isoprene, butadiene, and styrene. They are colorless, transparent, almost completely odorless, and have a low VOC content.

- The various types of KURARAY LIQUID RUBBER serve as reactive plasticizers and have a significantly higher molecular weight compared to other plasticizers. They are co-vulcanizable and significantly reduce migration. The use of KURARAY LIQUID RUBBER in the rubber compounding stage shortens the processing time while maintaining similar physical properties. Typical applications include tires, belts, hoses, and other technical rubber articles.

- Kuraray has developed a new type of liquid rubber (LIR, LBR, L-SBR) called liquid farnesene rubber (LFR). The product is based on natural and sustainable raw materials and contains a polymerized form of β-farnesene (a renewable monomer). Through established fermentation processes, proprietary yeast strains convert sugar sources (e.g., sugar cane) into β-farnesen

Lucant

Lucant from Mitsui Chemical is an ethylene/α-olefin oligomer and therefore a synthetic plasticizer oil. Compared to mineral oils, it gives EPDM compounds in particular improved processability, flexibility, heat and cold resistance, and optimized lubrication and defoaming properties. This makes Lucant an excellent choice for applications such as conveyor belts, dampers, and seals. In particular, mechanical properties such as tensile strength and elongation at break at high temperatures are significantly improved by the use of Lucant, as are processing properties on the roller due to increased tackiness. Lucant can be used to significantly reduce the compression set of compounds. This property makes the product particularly suitable for use in damper applications. Lucant is available in different viscosities.

Natural softeners

Vegetable oils such as palm oil, soybean oil, rapeseed oil, and sunflower oil and their derivatives contain fatty acids that can have a softening effect on rubber.

- Process oils: RBD Vegetable Oils from Ergon International are environmentally friendly process oils that have been specially developed for use in rubber compounds. These oils can be produced from refined, bleached, and deodorized vegetable oils. This makes them a sustainable alternative to conventional mineral oils. They offer excellent thermal stability and oxidation resistance. This extends the service life of rubber products. In addition, RBD Vegetable Oils improve the mechanical properties of rubber compounds by increasing flexibility and elasticity. Their low volatility results in reduced emissions of volatile organic compounds (VOCs). Overall, RBD vegetable oils from Ergon International contribute to the manufacture of high-performance, long-lasting rubber products that function reliably in both hot and cold environments.

- Epoxidized soybean oil is a derivative of soybean oil produced by epoxidation. Epoxol from FACI is often used as a natural plasticizer for rubber because it has a good plasticizing effect and is more environmentally friendly than some synthetic plasticizers.

- Other natural plasticizers include resins such as rosin, gum resin, and dammar resin, as well as coal tar pitch, which is a natural product obtained from the distillation of coal tar.

Special plasticizers

- Antistatic agents: Glyplast AS3 from Condensia is a polymeric plasticizer with high polarity that has been designed to improve antistatic properties. It is characterized by its ability to significantly reduce the electrical resistivity of rubber compounds after a short time through activation with air humidity. It is the only plasticizer on the market that produces this effect in carbon black-free compounds. This effect occurs on the surface and can be reduced or eliminated by abrasion. Glyplast AS3 is FDA approved.

- Alternatively, and in combination, Glyplast AS809 can be used. The antistatic effect of this plasticizer is not superficial, but acts within the rubber compound and therefore cannot be removed by abrasion or friction. Glyplast AS809 is not FDA approved.

- Demoulding aids: Glyplast 706/5 was developed specifically for demoulding polar ACM/AEM elastomer compounds. This water-based plasticizer oil reduces the number of cleaning cycles. It can be recovered by distillation and therefore reused several times.

Summary

Plasticizers are a key component in polymer processing. Their targeted selection and application can significantly influence the material properties and processability of polymers. They enable the manufacture of customized products with specific functions and thus make a decisive contribution to the performance of modern materials.

For more information, please contact:

NORCOMP silicone and

fluorosilicone compounds

Thermax® – The problem-solving Carbon Black