Voelpker: Nordmann Italy's partner for wax additives

Nordmann and VOELPKER work together to promote WARADUR® and CEVO® functional additives in the Italian market.

The many years of experience gained with traditional products based on montan wax derivatives has enabled Voelpker to develop cutting-edge additives that solve many processing-related problems. With new grades that have been specially developed for recycled plastics and formulations based on eco-sustainable materials, Nordmann has been able to expand its portfolio of innovative, sustainable and high-performance products to support its customers in the thermoplastics and molding sectors.

The CEVO® and WARADUR® product lines from VOELPKER make the perfect complement to Nordmann Italy's wax portfolio. We are constantly striving to partner with the world’s top manufacturers in order to provide our customers with comprehensive products and solutions of the highest quality.

ABOUT VOELPKER

With over 120 years of experience in the production of montan and specialty waxes, VOELPKER is one of the most experienced wax producers in Europe. VOELPKER develops and produces tailormade wax derivatives whose chemical functionalities and application properties are precisely adapted to the specific use.

VOELPKER is an independent, family run company with around 100 employees and is part of the German ≫Mittelstand≪. The production site is conveniently situated in central Germany. Our onsite Research and Development department continuously expands our range of possibilities by developing innovative solutions and products. Satisfied customers in more than 50 countries around the world trust our products.

CEVO® AND WARADUR® – MULTIFUNCTIONAL WAX ADDITIVES FOR ENGINEERING PLASTICS

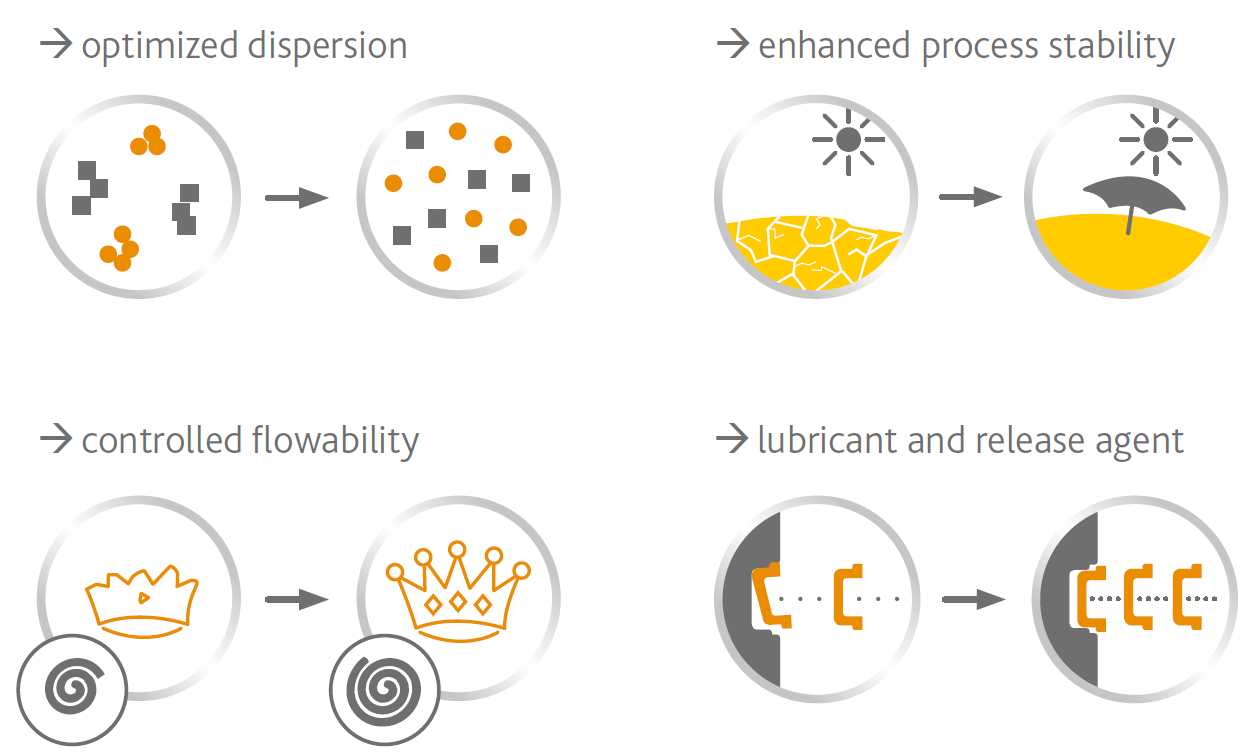

At the heart of the CEVO® and WARADUR® special wax additives from VOELPKER is their unique multifunctionality. This enables the simultaneous resolution of different plastics processing problems. It leads to improved filler or pigment dispersion and surface quality, improved flow and mold release properties and the reduction of undesired friction peaks during the polymer processing. The polymer and sensitive ingredients such as flame retardants are thus protected from unwanted degradation. CEVO® and WARADUR® additives also enable the production of particularly high-quality compounds containing recyclate.

CEVO®: SPECIALLY DEVELOPED FOR YOUR APPLICATION

What began as a service for our customers has, over time, become a passion: additives developed by our chemists and experts that are perfectly focused to the required polymer and application. With the CEVO® products, the innovation potential of specialized waxes can be fully exploited. CEVO® results additives can be used to solve processing- and application-related challenges.

For example, when it comes to good distribution of the material used, fast injection, filling long flow paths, the avoidance of friction peaks, fast demoulding, or the process stabilization of the compound to be produced. This is how we help you to continue to improve your product performance and keep pace with technical progress.

Montan wax additives have proven to be practically irreplaceable, particularly in demanding polymere applications. CEVO® is a forward integration of montan wax additives know-how in the direction of customer applications.

We think ahead and strive to understand the requirements and challenges of our customers even better. We develop ready to use additives for specific processing challenges and final product quality requirements.

CEVO® effects

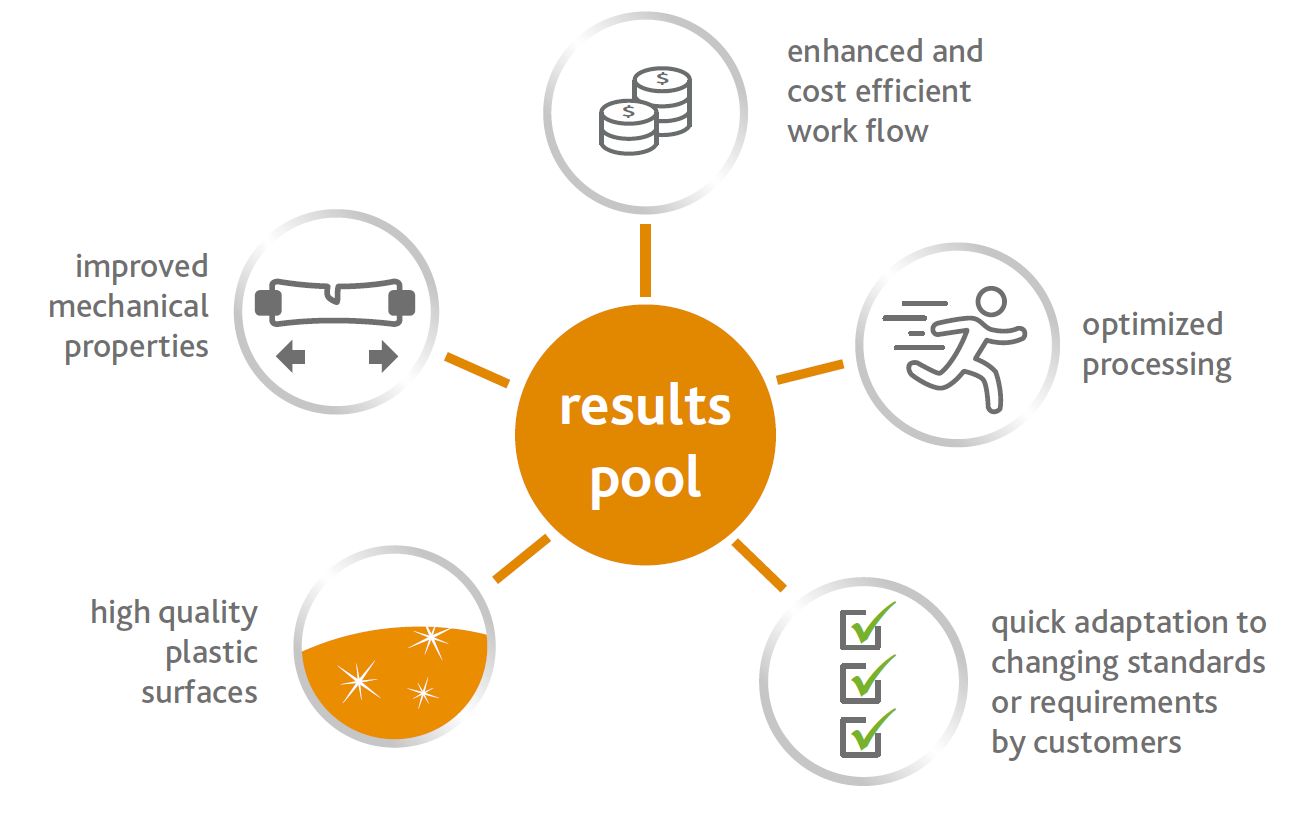

CEVO® results

CEVO® WAX ADDITIVES: POLYMER-SPECIFIC FORMULATIONS FOR ENGINEERING PLASTICS

| Polymer | Product | Flow improvement | Release effect | Dispersion | Other |

|---|---|---|---|---|---|

| PA | CEVO®-process A-3100 CEVO®-process A-3105 CEVO®-process A-3110 | +++ +++ +++ | ++ ++ +++ | ++ +++ ++ | Surface improvement Friction reduction Stabilisation |

| PO (PP/PE) | CEVO®-process J-3460 CEVO®-process B-3680 CEVO®-process B-5200 CEVO®-master B-6000 | ++ ++ ++ +++ | +++ ++ ++ ++ | +++ +++ +++ +++ | Surface improvement Compatibilization One pack, stabilization Compatibilization |

| PET/PBT | CEVO®-process J-3400 | ++ | ++ | +++ | |

| PC | CEVO®-process J-3400 CEVO®-process J-4055 CEVO®-master D-2050 | +++ ++ +++ | ++ ++ ++ | +++ ++ ++ | Dispersion of CF Dispersion of CF Chemical viscosity modifyer |

| POM | CEVO®-stab F-5510 | ++ | ++ | ++ | Formaldehyde binding, stabilization |

| TPU | CEVO®-process J-3405 | ++ | +++ | ++ |

CEVO® 3680

Post-consumer HDPE/LDPE waste in most cases contains unwanted polymer particles and mineral or other contaminants — which interfere with the manufacture of recyclates and degrade quality. CEVO® 3680 causes their correct dispersion as well as the dispersion of fillers. This enables adequate recycling qualities, e.g. for injection molding.

CEVO® 5515

CEVO® 5515 stabilizes the compounding and processing of polyacetal, as well as POM homo and POM co-polymers. POM easily splits off formaldehyde when exposed to multiple thermal loads. The addition of the additive not only suppresses the formation of unpleasant odors during compounding, but also reduces polymer degradation and thus an impairment of the quality of the injection molded parts.

CEVO® 6000

The masterbatch CEVO® 6000 was developed for a wide range of applications in the field of polyolefin recycling. Both in the area of post-consumer recycling materials and in the area of compounds based on post-industrial waste, the additive reduces the typical compatibility problems that arise from contamination with foreign polymers. At the same time, the use of CEVO®- 6000 leads to a basic or processing stabilization of the resulting product.

CEVO® master D-2050

The chemical modifier CEVO® master D-2050 was developed to increase the flow behaviour of highly viscous polycarbonates for example from post-industrial areas and it is primarily used in the production of easy-flowing polycarbonate compounds.

CEVO®-clean 1819

CEVO®-clean 1819 is a highly efficient and cost-effective cleaning concentrate for thorough and user-friendly cleaning of extruders. The special effectiveness of CEVO®-clean 1819 is based on a combined chemical-physical mode of action with optimally coordinated solid solvents and non-abrasive minerals for metal surfaces. CEVO®-clean 1819 is an innovative 'one-for-all' concentrate that can be used for almost all common thermoplastics. This makes its use particularly cost-effective. When used, it is always diluted with the next polymer to be used. CEVO®-clean 1819 is used as a dry blend of 20 - 25 parts concentrate and 75 - 80 parts of the unfilled polymer.

WARADUR® WAX ADDITIVES: PERFORMANCE AND BROAD APPLICATION SCOPE

WARADUR® montan waxes are proven as high performance additives in the plastics industry, due to their unique proper-ties and versatility. Montan wax derivatives serve for example as combined external and internal lubricants, dispersing agents and surface improvers in many types of plastics and processing methods (Table below). They are therefore particularly valued for technically challenging tasks in the engineering plastics field where high demands are placed on functionality, optical appear- ance and cycle time reduction.

Montan wax additives are the most multifunctional additives for engineering plastics

| Polymer | Flow improvement | Release effect | Dispersion |

|---|---|---|---|

| PA | montan wax | amide wax |copolymer wax | wax esters |polyol esters | montan wax | copolymer wax metal soaps | polyol esters | wax esters | montan wax polyol esters wax esters |

| PP (reinforced) | montan wax | copolymer wax |polyol esters | montan wax | amide wax |wax esters | metal soaps | montan wax polyol esters |

| PET/PBT | montan wax | polyol esters |wax esters | montan wax | PE wax | wax ester | montan wax polyol esters |

| PC | montan wax | wax esters | montan wax | PE wax |oxidised PE wax | polyol esters | wax esters | montan wax polyol esters |

| POM | montan wax | amide wax | complex esters | polyol esters | wax esters | montan wax | amide wax | oxidised PE wax | polyol esters | fatty acids | amide wax polyol esters |

| TPU | montan wax | complex esters | polyol esters | montan wax | amide wax | complex esters | polyol esters | montan wax |

| Styrenics | montan wax | oxidised PE wax |wax esters | polyol wax | amide wax | montan wax | PE wax | polyol esters | wax esters | amide wax montan wax polyol esters |

WARADUR® S-R

is a mixture of straight-chained monocarboxylic acids with a chain length in the range of mainly C28 – C32 (montanic acids).

WARADUR® E-R

is an ester wax consisting of esters of montanic acids with ethylene glycol.

WARADUR® GE

is a glycerol ester wax of montanic acids and exhibits a slightly higher molecular weight than WARADUR® E. Both esters exhibit chain length in the range of mainly C58 – C66 and provide low volatility, good thermostability and low migration rates.

WARADUR® GSM and WARADUR® ESM

are innovative hybrid ester waxes consisting of a mixture of long chain (mainly C28 – 32) wax acids montan esters and fatty acids esterified with multihydroxyl alcohols. They combine, on a molecular level, the chemical properties of montan esters and oleo esters. Both esters combine in an ideal manner the properties of montan esters (high thermal stability, low volatility, no blooming out, excellent release/anti sticking) and fatty esters.

WARADUR® OP-R

is an ester wax consisting of esters of montanic acids with multihydroxyl alcohols and contains calcium montanate.

WARADUR® OPplus

is also a montan wax based special wax consisting of esters of montanic acids with multihydroxyl alcohols. In addition, WARADUR® OPplus contains an increased amount of calcium montanate and fatty acid salts.

WARADUR® GSA

is a high-molecular complex ester of montanic acids.

The advantages that arise are manifold:

- Cost savings through shorter cycle times and, due to improved dispersion: optimized amounts of fillers, pigments etc.

- An even distribution of fillers also has a positive influence on the mechanical properties of the polymer and the surface quality.

- Flame retardants and other functional additives are protected from unwanted degradation by reducing friction peaks and their effectiveness is optimized through even distribution.

GENERAL ADVANTAGES AT A GLANCE

WARADUR® montan waxes and CEVO® formulations deliver specific solutions which comprise:

- Suitability for highly demanding plastic applications

- Improvement of processing and end product properties

- Internal lubrication: improvement of flow properties

- External lubrication: improvement of mould release

- Reduction of friction peaks, stabilization and protection of the materials

- No blooming-out, no exudation or product loss

- Improvement of pigment/filler/flame retardant dispersion

- Improvement of mechanical properties

- Effectiveness - improvements in functional additives

- Suitability for clear applications

For more information, please contact: