What makes a white pigment white?

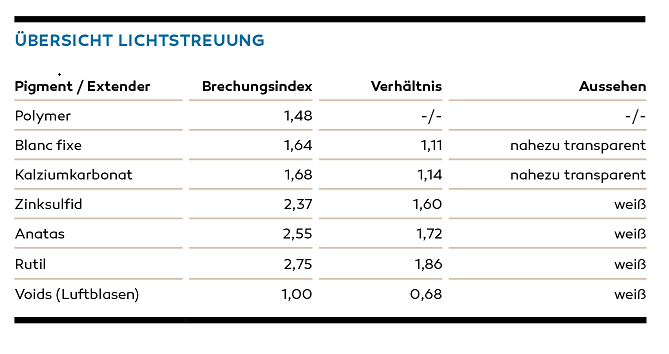

Light scatter within any medium comes down to the difference in the refractive indices between the pigment or extender it contains and the medium itself. If the ratio of these refractive indices is close to one, the whole system will have a transparent appearance. The system will only appear white in color if the ratio is significantly different from this value:

With respect to the high refractive index necessary for creating white pigments, there is a limited number of options. The most common of these is to use rutile titanium dioxide pigments, followed by anatase titanium dioxides and zinc sulfide-based pigments. The least effective option is air bubbles, also known as “voids”. All four of these materials work independently and can be used separately or in conjunction with one another.

Extenders enhance the efficiency of white pigments, but alone they are merely transparent or in some cases a bit milky. In BOPP or BOPET films, extenders create tiny, uniformly shaped air bubbles when the materials are stretched. These air pockets then perform the same role that white pigments would.

White is not always the same

Almost any commercial product or article that we can think of these days is available in the color white. However, when you look at different types of white cars or even white shirts, for example, it becomes very clear that the color is not always the same. In fact, there are many different shades of white. Why is this so?

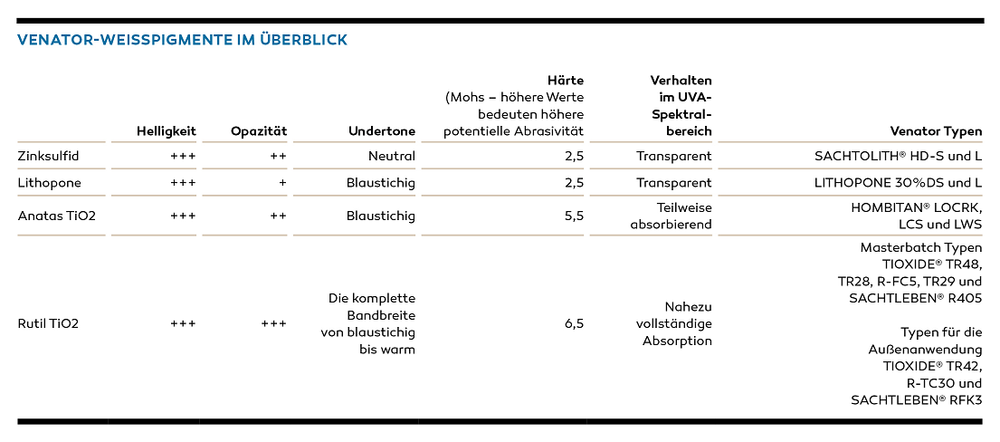

In order to create pigments with the brightest blue-white tones, it is essential for them to reflect as much light as possible in the visible part of the solar spectrum. By controlling particle sizes and distribution of white pigments with the utmost precision, Venator creates products which have very high opacity and different color shades. However, shades of white will also depend on processing, any coatings applied to the pigment and on the production route itself (i.e. chloride or sulfate).

Venator supplies rutile titanium dioxide pigments with highest refractive index, and as well anatase pigments and zinc sulfide-based pigments.

So-called spacers can be used to improve the performance of titanium dioxide pigments by preventing crowding and keeping white pigment particles at appropriate distance.

Using a blanc fixe (i.e. synthetic barium sulfate) such as Venator’s Blanc fixe Micro PLUS is well-suited to this sort of task. With a particle size that corresponds to the wavelength of visible light, blanc fixe creates enough space for at least one complete light wave to pass between two titanium dioxide particles. At the same time, its small particle size ensures the maximum possible number of individual particles in order to optimize this geometrical effect.

Titanium dioxide and zinc sulfide-based pigments

Titanium dioxide and zinc sulfide-based pigments both have a high refractive index and show no absorption in the visible spectrum, making them comparable in terms of optics. However, the slightly higher refractive index of titanium dioxide makes it possible to achieve a higher degree of opacity at similar concentration levels. In addition, the products behave very differently outside the spectrum of visible light and zinc sulfide is much softer and less abrasive than rutile titanium dioxide. Anatase pigments are also softer than rutile titanium dioxide but do not offer the same depth and brightness. They are purer in comparison, however, with generally fewer trace elements built in.

Venator markets a pure zinc sulfide pigment under the brand name SACHTOLITH®, as well as a range of pigments that combines zinc sulfide with barium sulfate: LITHOPONE. Venator’s anatase pigments are supplied under the name HOMBITAN®. In addition, the company’s portfolio also includes a lot of titanium dioxide pigments that are suitable for a variety of interior and exterior applications and which are manufactured using both the chloride and sulfate processing routes.

Recently, TIOXIDE® TR29 was added to Venator’s portfolio as an ultra-low moisture titanium dioxide pigment suitable for the production of multi-layer thin films, as well as for use in applications in which low moisture is critical for maintaining the integrity of finished articles. The innovations Venator has launched within the last three years – i.e. TIOXIDE® TR48 for masterbatch and ABS compounds, and TIOXIDE® TR42 for durable applications such as PVC profiles and agricultural films – all continue to prove their worth and have made very successful additions to Nordmann’s plastics portfolio.

Distributed in the DACH region

For detailed product information please contact our experts: sales(at)nordmann.global