Velvetol®: Improving sustainability in polymer chemistry

Promoting sustainability without compromising performance

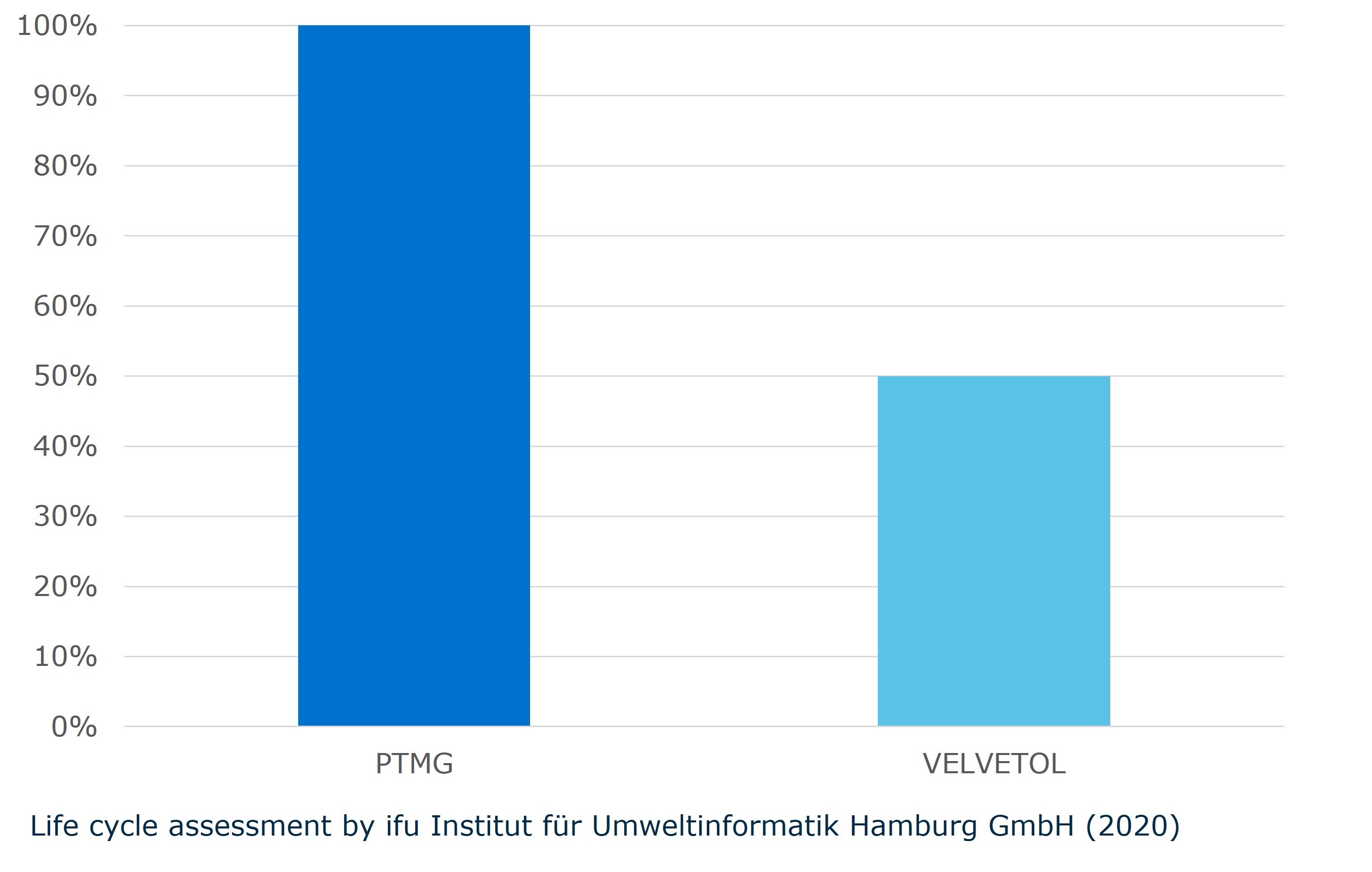

As a 100% bio-based 1,3-polypropanediol, it offers an excellent alternative to fossil-based products. In comparison to the production of petroleum based PTMEG Velvetol® offers up to 50% reduced global warming potential and up to 33% reduced non-renewable energy consumption.

Global Warming Potential

The global warming potential related to synthesizing Velvetol® is only half of that associated with PTMEG. This has been established by an ISO 14000 compliant life cycle analysis.

But what really sets Velvetol® apart is its ability to deliver exceptional performance alongside its sustainable properties.

Advantages for technical excellence

Molecular weight versatility

With a range of molecular weights, Velvetol® offers technical experts the flexibility to tailor formulations to specific application requirements, ensuring optimal performance in different scenarios.

Improved reactivity

Velvetol® has a high reactivity that speeds up synthesis processes and enables greater efficiency in production - a crucial factor for technical professionals who strive for precision and speed in their work.

Excellent hydrolysis resistance

Velvetol® offers exceptional hydrolysis resistance, which is critical for applications where durability and longevity are important. This property ensures that end products retain their integrity even under harsh environmental conditions.

Increased Toughness and Abrasion Resistance: Velvetol® increases the overall toughness and abrasion resistance of polyurethane components, providing engineers with materials that can withstand the rigours of real-world applications, from automotive components to industrial machinery.

Increased Toughness and Abrasion Resistance

Velvetol® increases the overall toughness and abrasion resistance of polyurethane components, providing engineers with materials that can withstand the rigours of real-world applications, from automotive components to industrial machinery.

Improved processing and handling

Velvetol®'s lower viscosity and melting point compared to conventional alternatives streamline processing and handling, simplify manufacturing processes and reduce energy consumption - an advantage for manufacturers seeking efficiency without sacrificing quality.

By enabling excellent properties in key applications VELVETOL® serves as a sustainable building block for the synthesis of polyurethane, co-polyetheramides and co-polyetherester as well as surfactants and many more.

- Thermoplastic Polyurethane Elastomers (TPU)

- Polyurethane dispersions (PUD)

- Thermoset polyurethane elastomers

- Spandex

- Copolymers

- PU foams

- Synthetic leather

- Coatings for various substrates

- Binders

- Lubricants

- Footwear and textiles

- Adhesives and sealants

Improving the performance of polymer formulations

In specific applications such as thermoplastic polyurethane elastomers (TPU), polyurethane dispersions (PUD) and polyurethane elastomers, Velvetol® offers many benefits:

- TPU: Improved processing, reduced Shore hardness, excellent mechanical properties, high flexibility at low temperatures and high bio-content - all key factors for engineers seeking superior materials for demanding applications.

- PUD: Reduced color and pigment requirements, improved flexibility and adhesion, and superior abrasion resistance - features that improve the performance of coatings and adhesives in industries ranging from construction to electronics.

- PU elastomers: Improved toughness, elongation, tensile strength, compression set, dynamic properties, and flexibility at sub-zero temperatures - properties that are setting new standards in industries ranging from automotive to consumer goods.

The properties of Velvetol® vary with the molecular weight:

| Properties | Units | H250 | H500 | H1000 | H2000 | H2700 |

|---|---|---|---|---|---|---|

| Content | % | 100 | 100 | 100 | 100 | 100 |

| Molecular weight | Dalton | 200-300 | 400-600 | 900-1100 | 1900-2100 | 2600-2800 |

| Hydroxyl no. | mg KOH/g | 370-550 | 280-187 | 125-102 | 59.1-53.4 | 43.2-40.1 |

| Acid no. | mg KOH/g | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 |

| Na metal content | ppm | <10 | <10 | <10 | <10 | <10 |

| Peroxide content | ppm | <10 | <10 | <10 | <10 | <10 |

| Water | ppm | <500 | <500 | <500 | <500 | <500 |

| Color | max. 50 | max. 50 | max. 50 | max. 50 | max. 50 | max. 120 |

| Viscosity (40°C) | mPas | 40-60 | 90-120 | 200-300 | 750-900 | 1550-1850 |

| Density (40°C) | g/ml | 1.03 | 1.020 | 1.018 | 1.016 | 1.016 |

| Melting point | °C | <0 | 0-5 | 12-14 | 16-18 | 22-25 |

By helping manufacturers meet the increasing global need for more sustainable products, Velvetol® is truly boosting sustainability in polymers.

For more information, please contact:

EU SVHC regulations: Challenges and solutions for light stabilizers

Low-emission catalysts