RESONAC chloroprene latice

They ensure a longer service life and better sustainability.

The different types of bitumen available on the market are each characterized by their softening point and hardness. Bituminous products are used on a larger scale in road construction for roof coatings and structural waterproofing. The service life of these bituminous products can be extended by adding appropriate polymers as elasticizers. This reduces susceptibility to damage and also improves the sustainability of end products.

Bitumen emulsions can be anionic or cationic, depending on the choice of emulsifier. Generally, anionic chloroprene latex dispersions (CR latex) are used to modify anionic bitumen emulsions for roofing and waterproofing. Polymer-modified anionic bitumen emulsions have improved toughness, strength and elasticity, as well as low-temperature flexibility, higher crack resistance and hot strength.

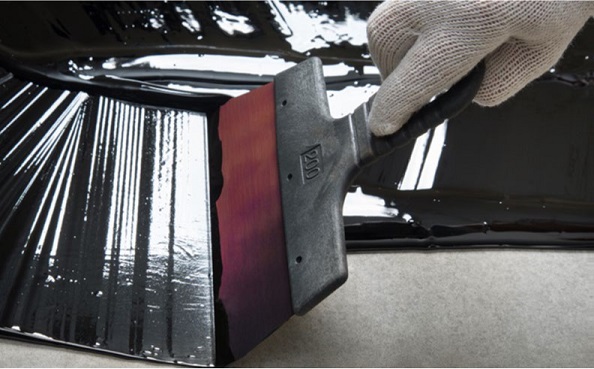

Compared to SBR or natural rubber, the use of CR latex liquid dispersions is more efficient for the same weight. They retain more of their original elastic properties after being incorporated into bitumen emulsions. They also offer better aging and weathering properties, better water resistance, more uniform rheology, lower flammability and a higher level of mechanical resistance than halogen-free polymers such as SBR or natural rubber. This makes CR latex liquid dispersions particularly attractive for use in waterproofing basements, as well as for applications that help protect roofs from the elements. RESONAC Chloroprene 671A is supplied as an optimal anionic liquid dispersion for modifying anionic bitumen emulsions. It has a high solids content (typically 59%), a high gel content that minimizes water-swelling, and a medium crystallinity that provides an optimum blend of elasticity and tensile strength. RESONAC Chloroprene 671A is physically mixed into bitumen emulsions under low to medium shear at ambient temperature and pressure. Other ingredients are added subsequently. The amount of RESONAC Chloroprene 671A used in each application varies from 5% to 20% (by weight). Application is done by spraying, brushing or rolling.

Showa Denko becomes RESONAC

As of January 1, the Showa Denko Group is now the RESONAC Group.

Distributed in Austria, Bosnia, Bulgaria, Croatia, the Czech Republic, Denmark, Estonia, Finland, Germany, Hungary, Iceland, Latvia, Lithuania, Norway, Poland, Romania, Serbia, Slovakia, Slovenia, Sweden and Switzerland.

For detailed product information please contact our experts: sales(at)nordmann.global