Pigment chips for biodegradable packaging

The market is continuing to demand more sustainable solutions these days, especially when it comes to packaging. European consumers, for example, tend to choose items with cardboard packaging rather than plastic or metal. The reason for this is simple: cardboard is easier to recycle. Food and cosmetics companies are working hard to adapt to these preferences and produce more sustainable packaging.

Compostable pigment chips by Mifar

Nordmann partner Mifar is pushing the development of sustainable solutions for food packaging, supplying an innovative range of compostable pigment chips.

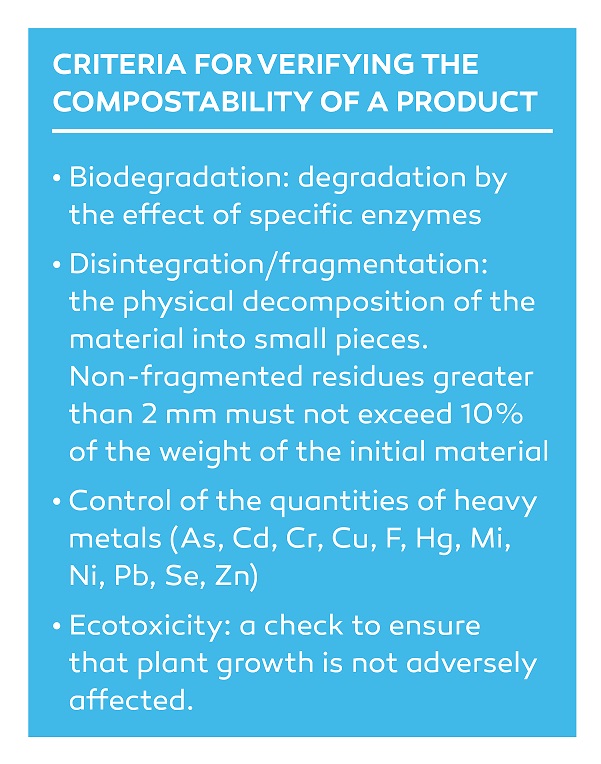

Developed in collaboration with BASF, the pigment chips contain nitrocellulose as a binder and are biodegradable and compatible with compostable printing media. They have been certified by the TÜV Austria Group according to the OK compost INDUSTRIAL standards, which means that the Compostable Chips meet the requirements of EN 13432:2000 for compostability. In turn, this European standard is based on the essential criteria of the Packaging and Packaging Waste Directive (94/62/EC), which has set new recycling targets for all packaging waste (65% by 2025 and 70% by 2030). Furthermore, Mifar’s new Compostable Chips are largely free of heavy metals (again, in accordance with EN 13432:2000) and will not have a negative impact on the composting process.

Developing new color indices

The development of compostable chips has also opened up possibilities for new color indices in printing, as traditionally used organic pigments do not meet the requirements for compostability and biodegradability.

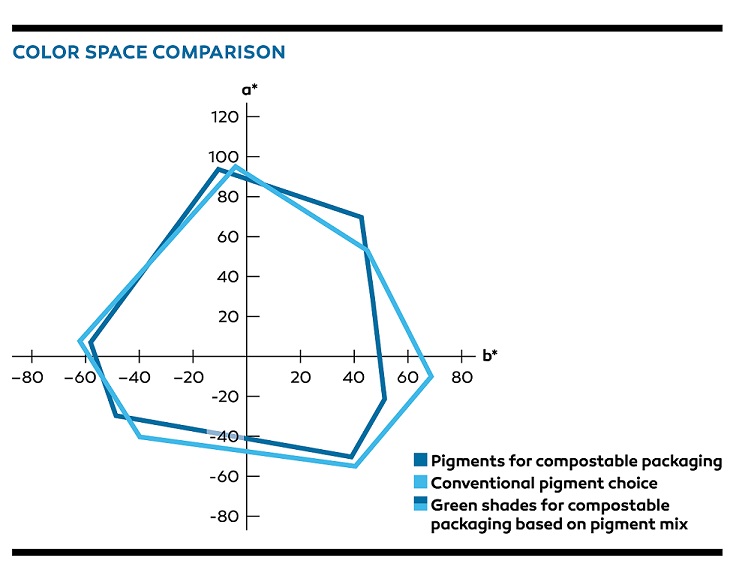

Compared to Mifar's classic pigment chips in terms of color space, the new compostable ones:

- generally overlap well

- have a slightly smaller red or green color space

- have a slightly larger yellow and orange color space

Mifar's compostable chips offer manufacturers the advantage of being able to produce just the right amount of finished product for their needs, eliminating the milling process. Using a Cowles dispersing blade, the chips can be incorporated in just 90 to 120 minutes, depending on the working conditions. This is ideal for producing small batches ranging from 100 to 1000 kg.

Being a solid and pre-dispersed pigment preparation in resin, the chips can safely be kept in the 20 kg packages they come in. This reduces storage risks.

Distributed in Europe (excl. France, Portugal, Spain)

For detailed product information please contact our experts: sales(at)nordmann.global