Nordmann and Kuraray are ready for the future

One of the major challenges facing the automotive industry today is how to increase the driving range of electric vehicles. The search for greater efficiency, too, has created a trend toward battery systems that use higher voltage. While earlier electric cars featured 300-400 VDC batteries, for example, modern models like the Porsche Taycan are able to take advantage of 800V voltage. Aggregates that can withstand such voltages require high-performance insulation materials that are also very lightweight.

GENESTAR™ materials enable both when used in battery components. They are used as weight-saving metal alternatives and, thanks to their high tracking resistance, are also high-performance insulation materials – and Kuraray has put its GENESTAR™ PA9T materials to the test on its own test bench in order to evaluate their limits. The results? Findings show that GENESTAR™ products top the current maximum voltage limit of 600V. Even at 750V, three common grades of GENESTAR™ showed no electric breakdown.

Comparative tracking index

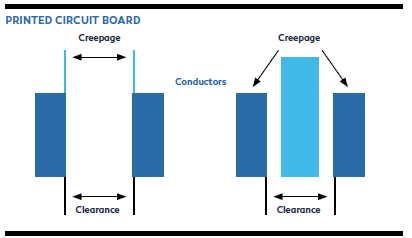

Electrical breakdown, also known as tracking, is the formation of a conductive path across the surface of an insulating material. In most cases, this occurs as a result of a breakdown of the material itself. For comparison and design reasons, a material’s resistance to tracking is expressed by its Comparative Tracking Index (CTI), which is the highest voltage at which a material can withstand 50 drops of a corrosive ammonia salt solution without tracking. Materials with a high CTI demonstrate better resistance to tracking and allow for parts to be designed with smaller creepage distance (see Figure 1) between conductors than specified in IEC 60664-1 standards.

Figure 1: Creepage (shortest distance along the surface of an insulation material between two conductive parts) vs. clearance (shortest distance through air between two conductive parts)

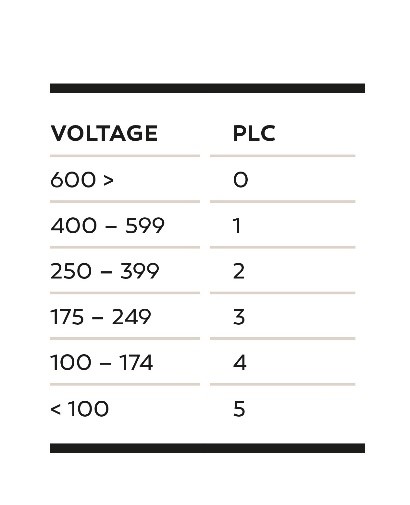

To improve repeatability and comparison standards, various performance level categories (PLC) were introduced (see Table 1). The highest class materials were ranked as 0, indicating that no tracking occurred even at 600V. Nowadays more and more plastic materials are rated as PLC 0, either due to their natural properties (such as with polyphtalamides, or PPA) or through the use of additives that increase the tracking resistance of certain types of PPS and PBT.

With trends moving toward ever higher voltages and ever smaller vehicle parts, thinking beyond the current PLC classes could represent the next opportunity for improving electric vehicles. How much further beyond 600V, for instance, can the PLC table be extended? What is the real limit?

Out of scientific curiosity, Kuraray’s research and development department began to dive deeper into this question with a series of tests, looking for the limits of its GENESTAR™ PA9T product family. GENESTAR™ PA9T resins are long-chain PPA characterized by low water absorption. Most grades – ranging from unreinforced to halogen-free V0 types with 30% glass fiber reinforcement – have a CTI greater than 600V or PLC Class 0.

Table 1: PLC classes correspond to maximum voltage

Test findings

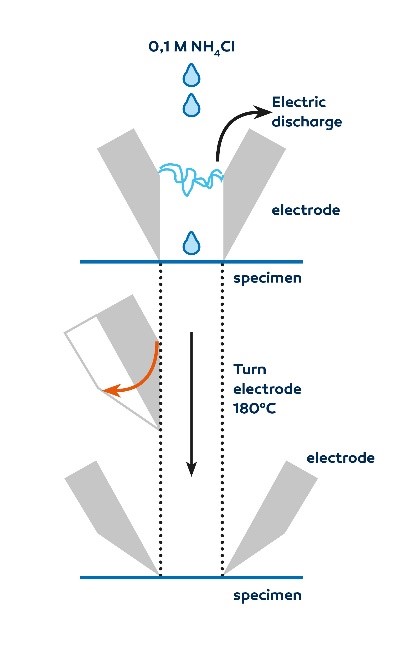

In a first attempt to assess the limits of the GENESTAR™ PA9T resins, CTI measurements were carried out according to the IEC 60112 standard. Voltage was ramped up to 625 V, and it turned out that the apparent 600V limit of the current PLC classes was most likely a result the test setup, since tracking occurred through the air in some cases (Figure 2, above). It was assumed that this breakdown had been caused by the edge of the electrode, as studies show that the presence of such an edge causes a higher field strength than does a flat surface. To circumvent this issue, the electrodes were rotated 180°. This resulted in a larger distance being created between the electrodes and the opposite electrode edge, while keeping clearage distance the same (Figure 2, bottom).

Figure 2: Turning the electrodes 180° allows CTI to be measured beyond 600V

After making this small adjustment, voltage could be increased to 750V without affecting tracking capability. This was confirmed by a control measurement using a material with a CTI of 550V.

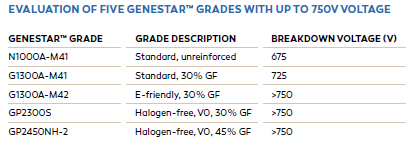

Five different GENESTAR™ materials were then measured using this setup (see Table 2) with test voltages of up to 750 V. For only two, a standard unreinforced (N1000A-M41) and a standard 30% GF grade (G1300A-M41), tracking at 675V and 725V was observed respectively. For the other three varieties, no tracking was shown at even 750V.

It should be noted that inorganic fillers such as glass fibers were shown to have a positive effect in testing, as all the GF-reinforced grades of GENESTAR™ materials demonstrated higher tracking resistance or in fact did not cause discharge at all at 750V. For the unreinforced types, the tracking that was observed at 675V is still well above the current maximum. Due to their higher ductility, too, excellent resistance to cracking from thermal shock can be assumed. For this reason, GENESTAR™ types represent an ideal choice for e.g. overmolded metal parts.

Table 2: Evaluation of GENESTAR™ materials

Although the experimental setup did not go beyond 750V, these findings demonstrate that there is great scope over 600V, as no tracking was observed for common GENESTAR™ products even at 150V above the limit.